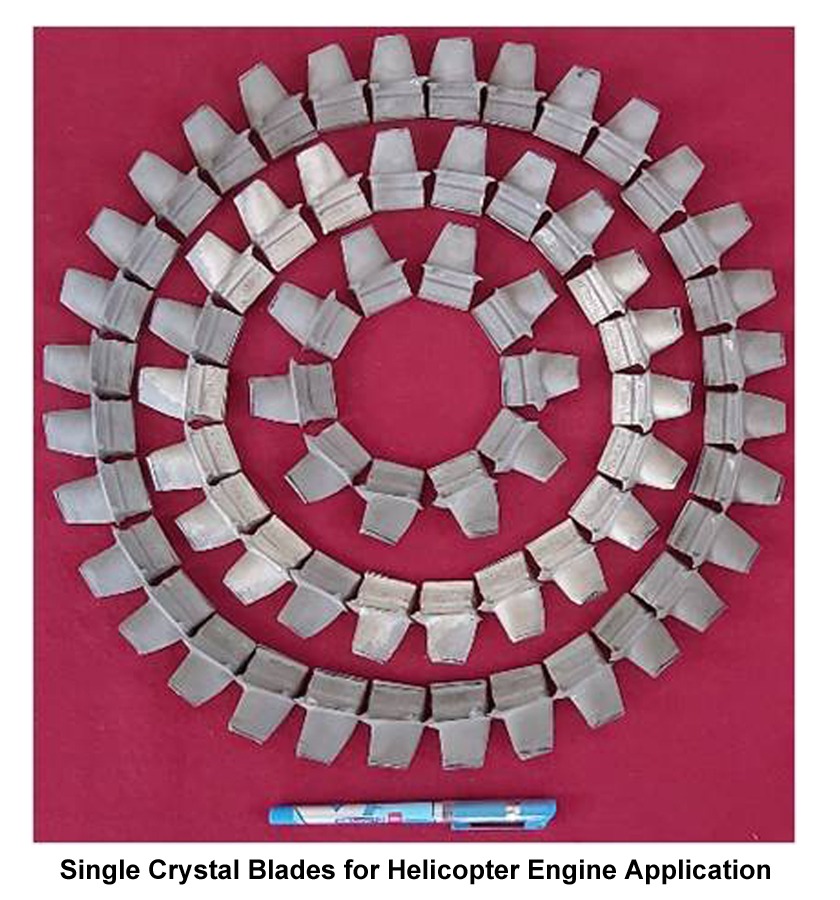

DRDO has developed single crystal blades technology and has supplied 60 number of these blades to HAL as part of their indigenous helicopter development program for helicopter engine application. This is part of a program taken up by Defence Metallurgical Research Laboratory (DMRL) a premium laboratory of DRDO to develop 5 sets (300 Numbers) of single crystal high pressure turbine (HPT) blades using a nickel-based super alloy. The supply of remaining 4 sets will be completed in due course.

DRDO has developed single crystal blades technology and has supplied 60 number of these blades to HAL as part of their indigenous helicopter development program for helicopter engine application. This is part of a program taken up by Defence Metallurgical Research Laboratory (DMRL) a premium laboratory of DRDO to develop 5 sets (300 Numbers) of single crystal high pressure turbine (HPT) blades using a nickel-based super alloy. The supply of remaining 4 sets will be completed in due course.

Helicopters used in strategic and defence applications need compact and powerful aero-engines for their reliable operation at extreme conditions. To achieve this, state-of-the-art Single Crystal Blades having complex shape and geometry, manufactured out of Nickel based superalloys capable of withstanding high temperatures of operation are used. Very few countries in the world such as USA, UK, France, Russia, have the capability to design and manufacture such Single Crystal (SX) components.

DMRL undertook this task based on its expertise gained during the development of such a technology for a aero-engine project earlier. Complete vacuum investment casting process to realize the blades, including die design, wax pattering, ceramic moulding, actual casting of components non-destructive evaluation (NDE), heat treatment and dimensional measurement, has been established at DMRL.

Special ceramic composition had to be formulated for making strong ceramic moulds which can withstand metallostatic pressure of liquid CMSX-4 alloy at 1500°C and above during casting operation. The challenge of maintaining the required temperature gradient has also been overcome by optimizing the casting parameters. A multi-step vacuum solutionising heat treatment schedule for complex CMSX-4 superalloy to achieve the required microstructure and mechanical properties has also been established. Further, a stringent non-destructive evaluation (NDE) methodology for the blades along with the technique for determining their crystallographic orientations has been developed.

Hon’ble Raksha Mantri Shri Rajnath Singh congratulated DRDO, HAL and industry involved in the development of critical technology. Secretary DD R&D and chairman DRDO, Dr G Satheesh Reddy congratulated and appreciated the efforts involved in indigenous development of this vital technology.