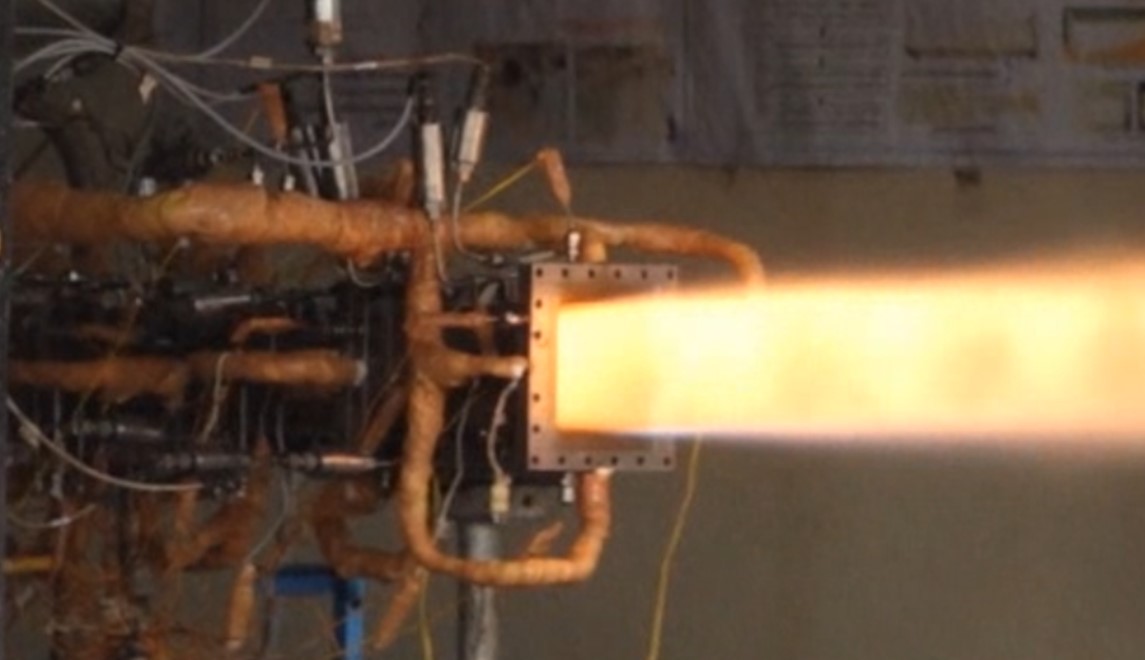

Defence Research & Development Laboratory (DRDL), a Hyderabad-based laboratory of Defence Research and Development Organisation (DRDO) has taken the initiative in developing a long-duration Supersonic Combustion Ramjet or Scramjet powered Hypersonic technology. DRDL recently developed these technologies and demonstrated a cutting-edge Active Cooled Scramjet Combustor ground test for 120 seconds for the first time in India. The successful ground test marks a crucial milestone in developing next-generation hypersonic missiles.

Hypersonic missiles are a class of advanced weaponry that travel at speeds greater than Mach 5 i.e., five times the speed of sound or more than 5,400 km/hr. These advanced weapons have the potential to bypass existing Air Defence Systems and deliver rapid and high-impact strikes. Several nations including USA, Russia, India and China are actively pursuing Hypersonic technology. The key to hypersonic vehicles is Scramjets, which are air breathing engines capable of sustaining combustion at supersonic speeds without using any moving parts.

The ground test of scramjet combustor showcased several notable achievements, demonstrating its potential for operational use in Hypersonic vehicles, like successful ignition and stable combustion. Ignition in a scramjet engine is like ‘keeping a candle lit in a hurricane’. Scramjet combustor incorporates an innovative flame stabilisation technique that holds continuous flame inside the combustor with air speed in excess of 1.5 km/s. Many novel and promising ignition & flame holding techniques were studied through many ground tests in arriving at Scramjet Engine configuration. Advanced Computational Fluid Dynamics (CFD) simulation tools were used for their evaluation & performance prediction.

The indigenous development of endothermic scramjet fuel, the first time in India, jointly by DRDL and Industry is central to this breakthrough. The fuel offers dual benefits of significant cooling improvement and ease of ignition. The team developed a special manufacturing process to achieve stringent fuel requirements of DRDL at Industrial scale.

Another key achievement is the development of state-of-art Thermal Barrier Coating (TBC) which is designed to withstand extreme temperatures encountered during hypersonic flight. A new advanced ceramic TBC having high thermal resistance & capable of operating beyond melting point of steel has been jointly developed by DRDL and Department of Science & Technology (DST) Laboratory. The coating is applied inside the Scramjet engine using special deposition methods that enhance their performance and longevity. With demonstrated capabilities in stable combustion, enhanced performance and advanced thermal management, this breakthrough sets the stage for next generation Hypersonic missiles.